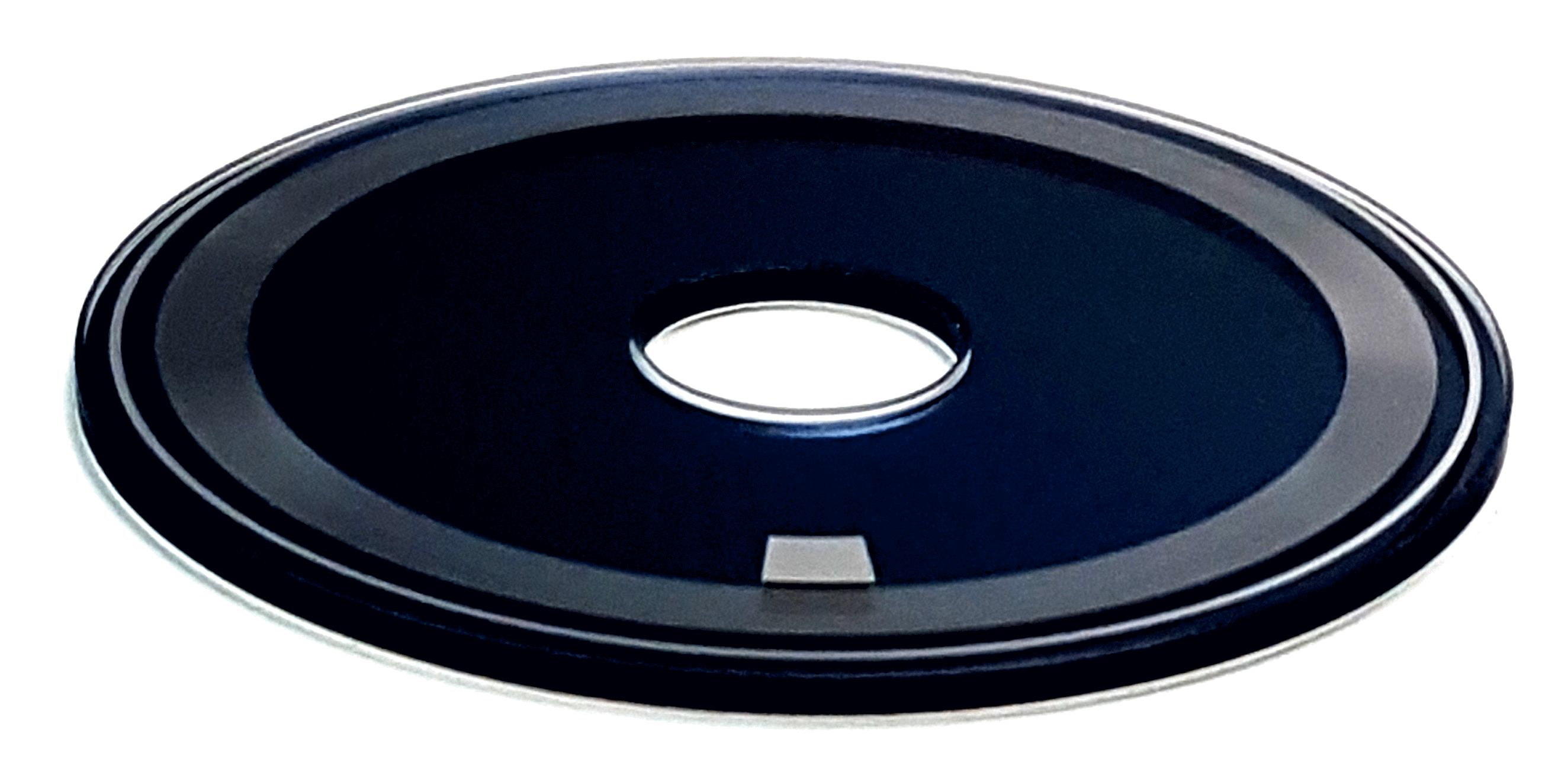

Rotary Scales

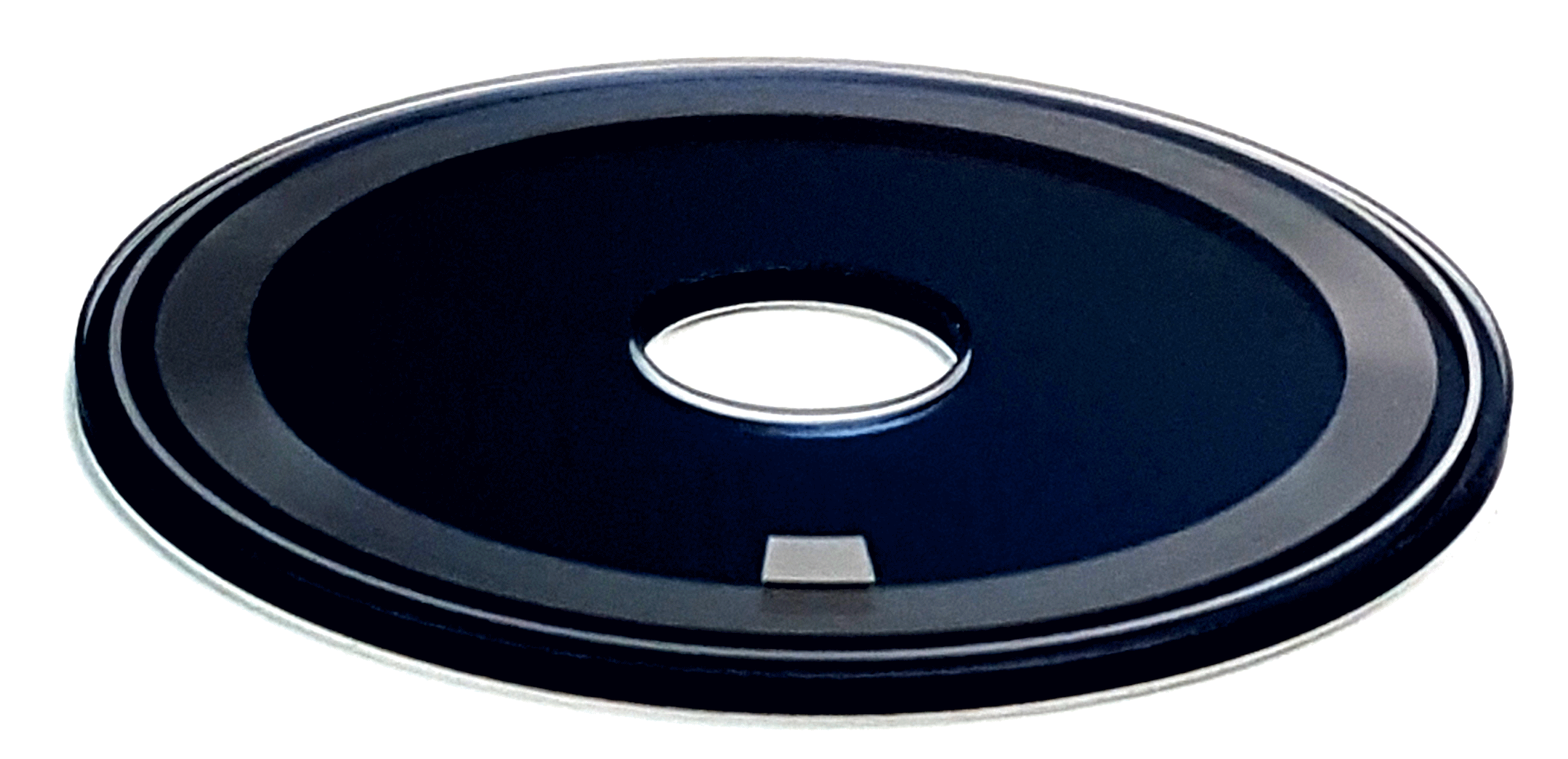

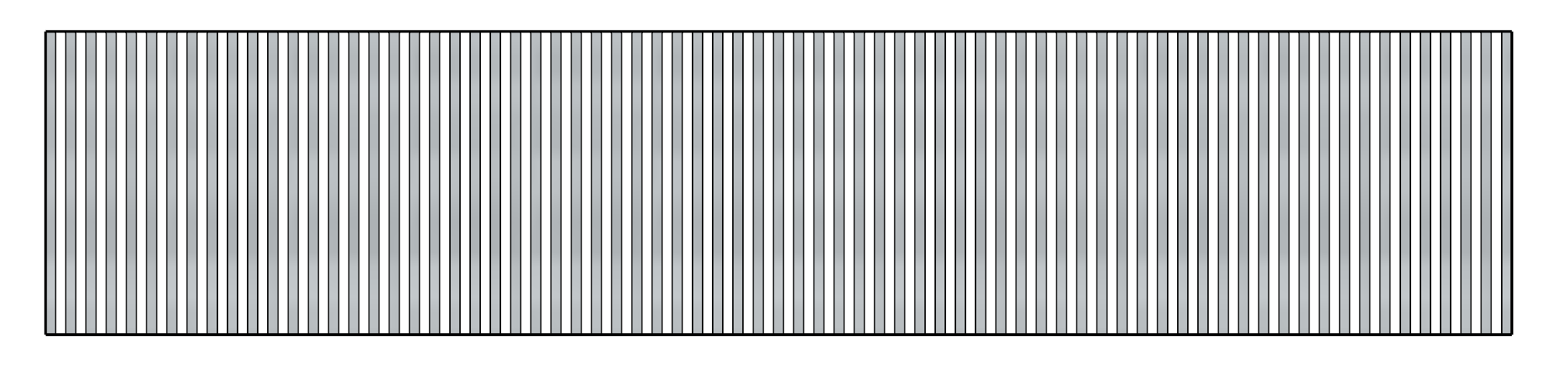

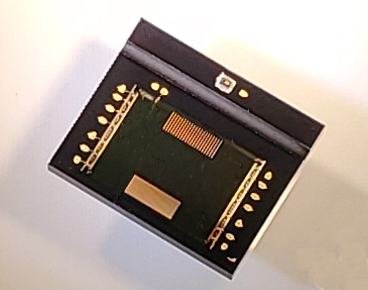

Precision Glass Rotary Scales (Codewheels)

- Precision Linear and Rotary Glass Scales

- Fine feature sub micron photolithography for maximum accuracy

- Multiple coating process options

- Reflective and Anti-Reflective coatings for different wavelengths

- Increase performance and lower power consumption

- UV curing options

- Up to 700mm Linear, Up to 150mm Rotary diameter

- Soda lime glass standard, low CTE & special glass available

Maximize performance of any optical encoder with precision glass scales by VC America Electronics.

VC America Electronics uses sub micron photolithography to create accurate and repeatable patterns. The process is capable of 2µm period (1µm reflective +1µm clear or anti-reflective) when needed. Common track periods between 20µm and 100µm benefit from the precise photolithography.

Production scales match the encoder, physical, environmental, and performance requirements. For applications requiring best accuracies over long lengths or temperature extremes, glass compositions with very low CTE are used.

Linear and Rotary scales are manufactured using soda-lime glass with chrome reflective and absorptive layers optimized for 630-640nm (Red LED) or 850nm, with dimensional precision and low defect density.

We offer standard scales for rapid evaluation and production and we also manufacture to custom specifications for unique pattern, material, and dimension requirements.

Rotary scales OD and ID are sawed and edges may be straight cut or beveled with chamfer or rounded edges.

| Symbol | Material | Specification | Tolerance | Units |

|---|---|---|---|---|

| OD Maximum | Soda-Lime Glass | Up to 150 | ±0.1 | mm |

| OD | Outside Diameter | ±0.1 | mm | |

| ID | Inside Diameter | ±0.1 | mm | |

| T | Thickness | ±0.05 | mm | |

| TTV | Total Thickness Variation | 10 | µm | |

| LTV | Local Thickness Variation | 5 | µm | |

| CTE | Temperature coefficient of expansion | 8.5 | 10-6mm/mm°C |

VC America Electronics uses sub micron photolithography to create accurate and repeatable patterns.

| Parameter | Reference | Minimum | Typical | Maximum | Units |

|---|---|---|---|---|---|

| Pitch/Period Accuracy | Local | ±1 | µm | ||

| Total | ±2 | µm | |||

| Metal pattern alignment to Axis | ±20 | µm | |||

| Chrome reflective layer | Standard | 50 | 54 | 60 | % |

| Augmented | 60 | 65 | 70 | % | |

| Enhanced | 88 | 93 | 98 | % | |

| Chrome absorptive(anti-reflective)@ 630nm | AR | <2 | 5 | % | |

Various coating processes are available to suit your application.

| Code | Precision Rotary | Mounting Adhesives |

|---|---|---|

| CG | Reflective chrome on clear glass | Epoxy, UV |

| AR | Reflective chrome topside with Anti-reflective layer bottom side | Epoxy |

| AC | Reflective chrome and Anti-reflective layer top side (in track area) and clear center zone | Epoxy, UV |

Lifecycle

Active

Rotary Glass Scales.pdf

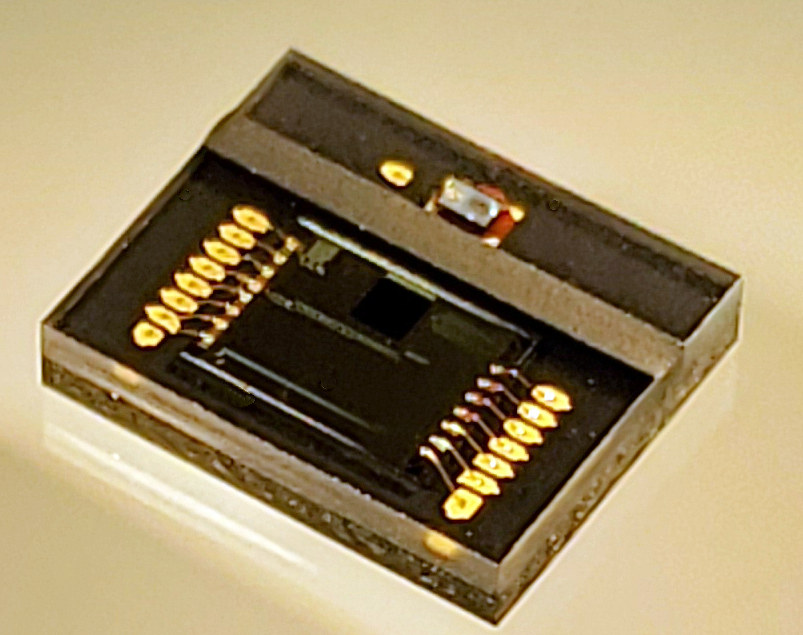

Rotary Glass Scales.pdf SMD-04B

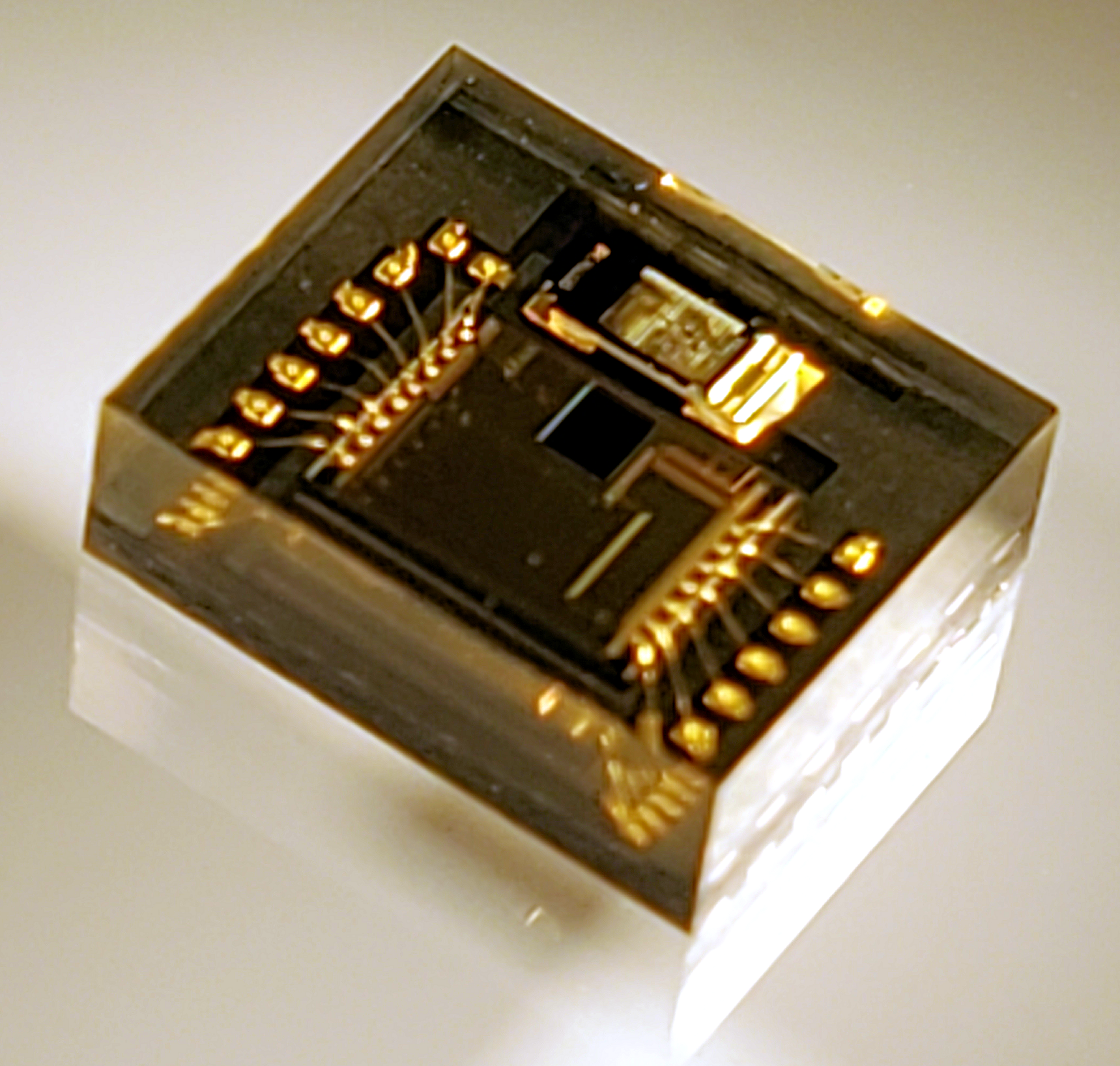

SMD-04B SMD-01B

SMD-01B SME-08

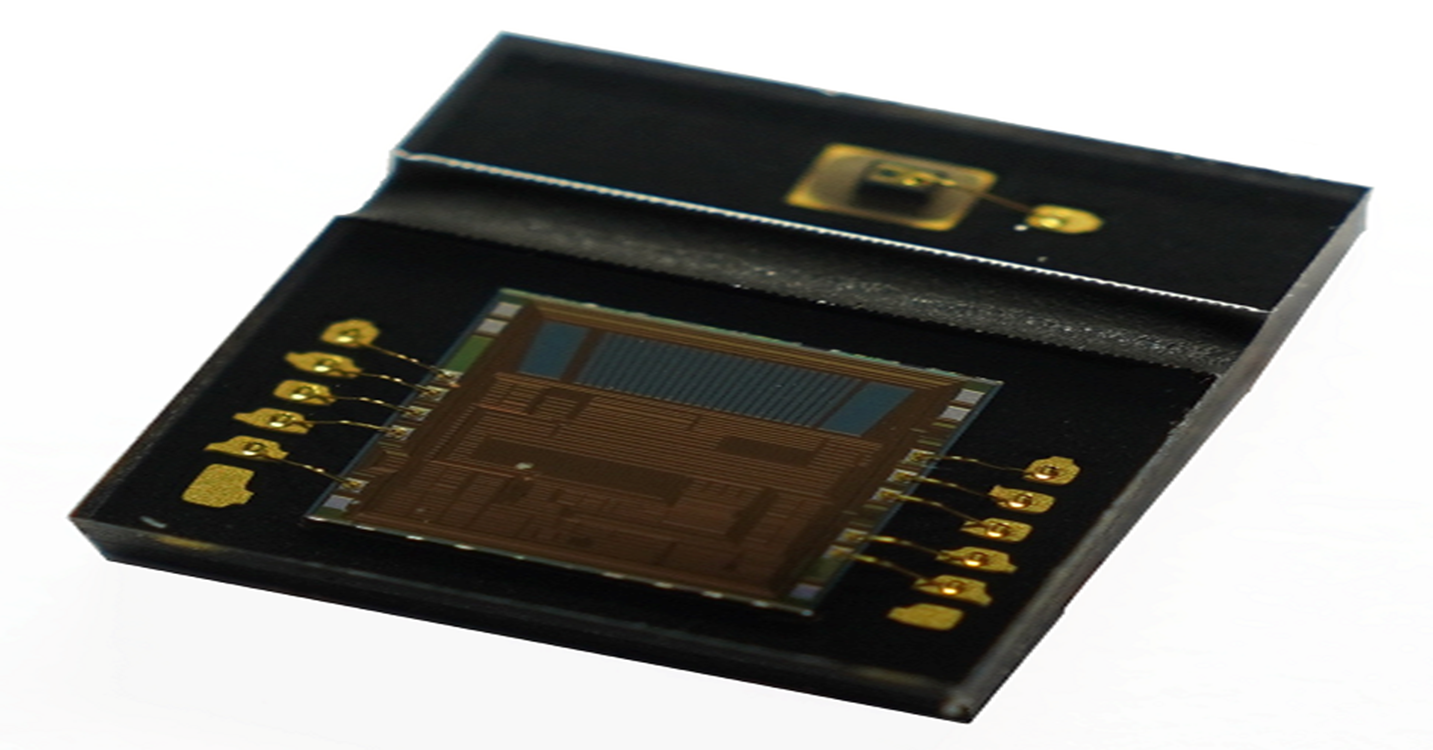

SME-08 Linear Scales

Linear Scales SM3414B

SM3414B